Applications of DIESEL-RK

DIESEL software has been designed since 1981 - 1982. In those

years it was applied in researches of many engines with different sizes, speed and

application. All these years the software is improving to grow efficiency and field

of application. Results of simulation in every research are compared with experimental

data obtained by various authors, mainly obtained by diesels manufacturers.

Main features of program DIESEL-RK are similar to known

thermodynamic programs. However, together with conventional features, the DIESEL-RK has

new advanced applications which are absent in other programs. DIESEL-RK is oriented on

diesel combustion optimization and ICE analysis and optimization. The assumption about

identical work of all engine cylinders allows considerably increase operating speed and

one makes it possible to resolve multiparametrical optimization tasks.

Main Applications

- Torque curve and other engine performances prediction.

- Fuel consumption prediction and optimization.

- Combustion and emission analysis and optimization.

- Knock prediction.

- Valve timing optimization.

- EGR system analysis and optimization.

- Turbocharger and bypasses matching and optimization.

- Research and optimization of fuel injection profile including multiple injection, sprayer

design and location as well as piston bowl shape optimization.

- Convert of diesel engines into gas engines.

- Dual fuel engine analysis.

High operating speed of DIESEL-RK permit resolving of

multiparametrical optimization tasks, including optimization of piston bowl shape and fuel

injection system to achieve low level of NO and smoke emissions.

Computational researches with optimization can be

carried out very fast and without large expenditures. The software does not require

powerful computer.

After termination of computing, data about fuel sprays

evolution including interaction of them are presented in a convenient form. It allows step

by step caring out optimal design of piston bowl and sprayer to achieve optimal conditions

of sprays evolution with minimal losses due to intersection of free sprays and wall surface flows

generated by sprays.

Some examples of researches and obtained results are presented

below.

|

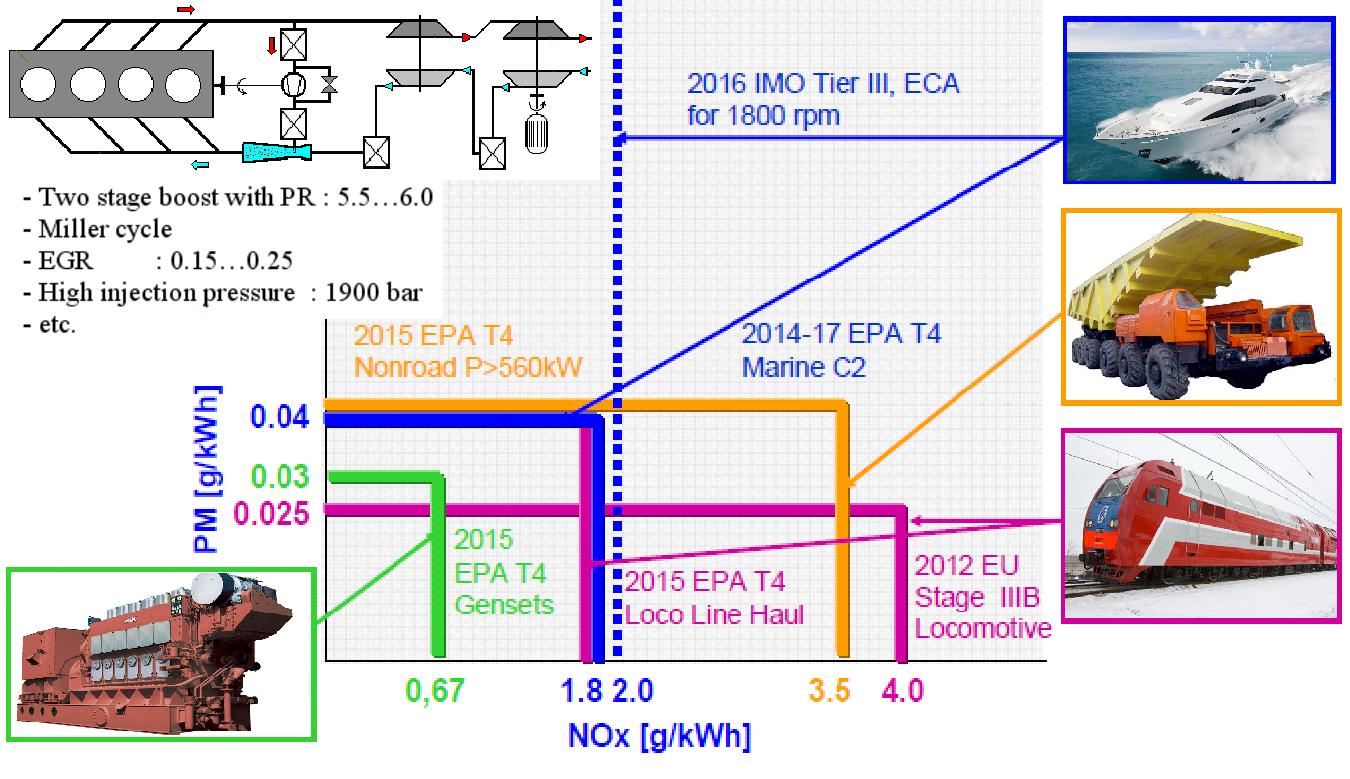

Optimization of medium speed diesel engine parameters to meet the 2012 EU

Stage IIIB regulations.

The research includes common optimization

of the following parameters:

- Intake Valve Timing (Miller cycle);

- Injector holes number, diameter, and orientation;

- EGR (with the account of a Venturi nozzle dimensions and power for EGR

pump drive...);

- Injection pressure;

- Injection profile shaping;

- Boost pressure;

- Compression ratio.

Automatic optimization is carried our at few operating points having own weight

coefficients...

See details >>

|

Matching the piston bowl shape and spray angle for the locomotive diesel.

Computational research and optimization of sprayer

nozzles orientation for different piston bowl shapes has been performed.

Analysis of fuel sprays evolution in contact with walls as well as

distribution of fuel in characteristic zones has been done for part load and

full capacity. Conclusion about dependence of optimal piston bowl shape on

BMEP was made. See

details>>

|

|

|

Simulation of mixture formation, combustion and NO emission in truck diesel with

different strategies of injection. Examples of simulation of mixture formation, combustion and NO emission in

one-cylinder truck diesel equipped with Common Rail fuel injection system

are presented in comparison with experimental data.

See

details>> |

Simulation of mixture formation and combustion in two-stroke

marine diesel with side injection system. An

example of simulation of mixture formation, fuel distribution and combustion in cylinder of

low-speed marine diesel is presented. Fuel sprays tip penetration (in

swirled air) were calculated and compared with experiment and with

calculated by CFD software. See

details>>

|

|

|

Development of Common Rail system controlling algorithm.

At

first, simulation of high speed diesel with Bosch VE fuel system was carried out over

whole operating range (with identical empirical coefficients). Calculated data are well

corresponded with experimental ones. Next step: at several operating modes the

optimization of injection parameters of Common Rail system was carried out to decrease NO

and PM emission. On a base of optimal solutions a map of injection pressure, injection

duration and injection timing was obtained for the whole operating range. See details>>

|

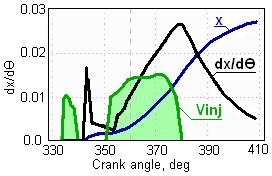

Simulation of medium-speed diesel combustion at split injection. An

example of simulation of mixture formation and combustion in cylinder of medium speed

locomotive diesel with double stage injection is presented. Heat release rate curves

obtained in calculation and in testing are compared. See

details>>

|

|

|

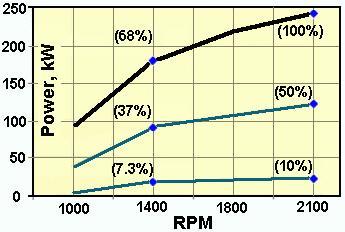

Simulation of diesels over the whole operating range.

After calibration of ICE

model, DIESEL-RK provides accuracy simulation of engine over whole operating range. Images

of mixture formation and heat release diagrams are presented for different operating modes

of:

- high-speed diesel. See

details>>

- truck diesel YaMZ-238D. See details>>

- medium speed locomotive diesel. See details >>

|

Simulation of gas exchange and combustion of truck diesel at different operating modes.

Calculated

and measured diagrams of heat release rate and pressures in cylinder and manifolds are

compared at different operating modes. Image of mixture formation and analysis of

allocation of fuel in characteristic zones are presented for full load. See details >>

|

|

|

Analysis of allocation of injected fuel in characteristic zones of

combustion chamber for diesel engines with different conditions of a mixture formation. See details >>

|

Calculation of a gas pre-chamber engine (diesel MTU 396 converted for

operation on natural gas). Comparison between calculated and experimental curves of

pressure in the cylinder and diagrams of prechamber pressure and temperature are

presented.

See

details>> |

|

|

Research aimed to decrease NO emission of naturally aspirated diesel.

Numerical

research of possibility to decrease a level of NOx emission of diesel engine by means of

optimization of the piston bowl shape, by veering of fuel jets evolution, by decrease of

injector nozzles diameter, by increase of compression ratio, etc. A sequence of

optimization steps and theirs results are presented. See details >>

|

Multiparametrical optimization of a medium-speed marine diesel at increase its

capacity. Research aimed to achieve minimal SFC at increase engine power by a

factor 25%. Optimization parameters include designed angles of HP and LP turbines nozzles

outlet of two-stage free turbocharger, valve timing, CR, etc. A sequence of

optimization steps and theirs results are presented. See details >> |

|

To home page

|