Diesel-RK is an engine simulation tool

DIESEL-RK is a full cycle thermodynamic engine simulation

software. One is designed for simulating and optimizing working processes of

two- and four-stroke internal combustion engines with all types of

boosting. The program can be used for modeling the following types of engines:

- DI Diesel engines, including PCCI and engines fueled by bio-fuels.

- SI petrol engines.

- SI gas engines including prechamber systems, and engines fueled by

different gases: Methane, Propane-Buthane, Biogas, Wood gas, Syngas, etc.

- Two-stroke engines with uniflow and loop scavenging, opposed piston

engines (OP or Junkers engines) and OPOC engines.

- Dual fuel engines (engines having few independent fuel injection systems for different fuels).

(Engines with RCCI)

The DIESEL-RK is a thermodynamic tool: engine cylinders are

considered as open thermodynamic systems.

Representative applications include:

- Fuel consumption prediction and optimization.

- Torque curve and other engine performances predictions.

- Combustion and emission analysis, including PCCI / HCCI.

- Dual fuel engine mixture formation and combustion analysis.

- Knock prediction.

- Valve timing optimization, including VVA optimization for every operating

mode.

- EGR analysis and optimization.

- Turbocharger and bypasses matching and optimization.

- Conversion of diesel engines into gas engines.

- Cooperation with different modeling tools: Simulink, IOSO NM, etc.:

DIESEL-RK solver can be run under the control of other applications.

Main features of program DIESEL-RK are similar to known

programs: WAVE (Ricardo Software), GT-Power

(Gamma Technologies) and BOOST (AVL). However, together with conventional abilities, the

program DIESEL-RK has new advanced features:

- RK-model : is

a multi-zone diesel fuel spray mixture formation and combustion model.

- Fuel Spray Visualization tool (easy flat and advanced 3D).

- Multiparametric and multidimensional optimization of engines parameters. A

target function including NOx, Soot and SFC simultaneously may be calculated

as inside DIESEL-RK, as with User Defined procedure being done as DLL and

linked with DIESEL-RK kernel.

- 1D and 2D parametrical researches procedures.

- Detail Kinetic Mechanism of NO formation (199 reactions, 33 species) is

implemented for PCCI, multiply injection and high EGR analysis. (Zeldovich

mechanism does not work correctly at large EGR and multiple injection. One

shows too small emission in comparison with experimental data.)

- DIESEL-RK support simulation of water injection and

account H2O condensation and evaporation in intake manifold, port and

cylinder.

RK-model simulates mixture

formation and combustion taking into account:

- Piston Bowl Shape: any geometrical shapes can be specified and saved into

the piston bowl data base which already includes the most common geometries;

- Different Swirl Profiles and swirl intensity;

- Sprayer Location: central, non-central, side injection, few

sprayers;

- Number, Diameter and Direction of sprayer nozzles (each

sprayer may have nozzles with different diameters and arbitrary orientation);

- Fuel Properties, including bio-fuels and blends of bio-fuels with diesel

oil (data base of fuels is supported);

- Shape of injection profile including multiple injection and PCCI;

Optimization of injection profile flanks shape; Optimization of Multiple

Injection Strategy;

- Detail Chemistry is calculated at the Ignition Delay prediction for PCCI

with diesel fuel and biofuel. RK-model accounts a CR high pressure effect on Ignition

Delay;

- Low Temperature Combustion is modeled at PCCI and HCCI;

- Interaction of the Sprays with Walls and with other Neighboring Sprays

(as on wall, as in volume);

- Local Temperature of the wall in the region of impingement the sprays with

a wall.

The RK-model has a capability to optimize the piston bowl shape and fuel

injection system parameters (sprays directions, diameter and number of nozzles)

as well as to develop multiple injection strategy and the Common Rail

controlling algorithm over the whole operating range.

| Fuel spray evolution visualization tool

The DIESEL-RK includes "Fuel Spray Visualization" code.

This code allows engineers to present in the animation picture format the

results of modeling of interaction of the fuel spray with combustion chamber

walls, air swirl and with neighboring sprays. The code assists in choosing

the best shape of the piston bowl and select the diameter, the number and

the directions of injector nozzles for a given injection duration and swirl

intensity. Results of simulation can be saved as Windows graphic files, AVI

or animated GIF files. Visualization is possible as flat picture, as in 3D.

|

|

3D visualization of sprays evolution in

cylinder of two-stroke low speed large marine diesel engine

3D tool allows analyze spatial evolution as of all sprays, as

of one or few sprays. Visualization tool has capabilities to mark each

characteristic zone of every spray by specific bullets to observe the volumes

where sprays impinge walls and disturb each other in volume or near the wall.

The combustion model accounts effect of these zones on Heat Release Rate. The

real shape of piston bowl and cylinder cover is accounted at simulation and

visualization. This function is very important for optimization of

combustion in large marine two-stroke diesel engines with side injection system.

In the pictures the sprays spatial intersection zones are

shown by light green bullets.

Effect of sprays spatial intersection on Heat Release Rate is

presented below. On the right HRR diagram the intersection phenomenon is not

accounted; in the left the effect is taken into consideration.

|

DIESEL-RK

preprocessor is very easy in use:

- Wizards allow beginners working without especial training;

- Detailed Engine Description provides wide range of research abilities

for experts.

Preprocessor makes it possible to set and research any piston bowl shape

and any fuel sprayer design. Data base of piston bowls is supported. |

| Optimization library and parametrical

research tools. To perform an optimization calculation the

DIESEL-RK is equipped with a built-in procedure of

multiparametric and multidimensional optimization which

includes 14 methods of nonlinear optimization search. There is also a

possibility to perform 1D and 2D parametrical search investigations.

Optimization tools allow engineers to considerable increase the efficiency

of computational research providing effective ways to improve the engine

design.

For simultaneous optimization of few engine parameters: NOx, Soot and SFC

the target function including list of engine parameters may be calculated

with User Defined Procedure being done as DLL and linked to the existing

DIESEL-RK kernel.

Pareto-optimization is possible if DIESEL-RK will be run

under control of external optimizer. |

|

SAE

Pap. No 2009-01-1956 |

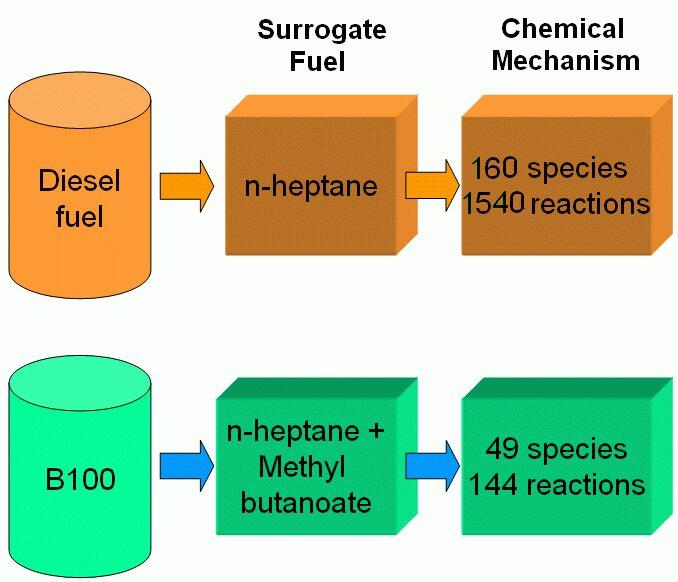

Premixed Charge Compression Ignition (PCCI) analysis.

Simulation of combustion at

Multiple Injection and simulation of the PCCI or Split Combustion

are supported. The specific feature of PCCI is a very early start of

multiple injections of pilot portions of fuel.

Low Temperature Combustion and High Temperature Combustion are modelled.

The Ignition Delay for every portion may be calculated using

different methods including user defined model, phenomenological models, or

Detail Chemistry Models, for example implemented Lawrence Livermore National

Laboratory mechanism which considers 1540 reactions between 160 species.

See detailes...

The DIESEL-RK interface includes special tool for multiple injection

specification. Using this tool it is possible to select and optimize

automatically a duration and fraction of pilots to exclude the hitting of

the fuel on the liner and to arrange optimal combustion . See

visualization. |

|

Simulation and

analysis of Bio-fueled diesel engines and Gas engines

The DIESEL-RK

combustion model supports the library of different fuels including different

blends of biofuels with diesel oil.

Physical properties of biofuel blends are used in the spray evolution

simulations and in modeling the evaporation and combustion processes.

The biofuel combustion modeling was done in collaboration with Dr. Khamid

Mahkamov in the

School of Engineering at Durham University (UK).

User-Defined Fuels properties are saved in internal data base of the

project. Different types of fuels can be specified for a certain mode of

engine’s operation. |

|

|

Properties of gas mixture of gas fueled engine are calculated

automatically depending on different gas fractions in the mixture. List of

supported gases includes 12 items and may be extended easily.

|

H2

O2

N2

H2O

CO2

CH4

CO

|

Hydrogen

Oxygen

Nitrogen

Water Vapor

Carbon Dioxide

Methane

Carbon Monoxide |

C2H6

C3H8

C4H10

CH3OH

CH3-O-CH3

C2H5OH

|

Ethane

Propane

Buthane

Methanol

Dimethyl Ether (DME)

Ethanol |

|

Kernel can be run under a control of external

application. In order to run DIESEL-RK kernel under the control of external codes

intended for optimization or for simulation of vehicle where the engine has

been used, the special interface is developed. The interface includes text

files with input data and output data. The DIESEL-RK solver may be run by

external code via batch file.

For example DIESEL-RK is compatible with multi-objective optimization

software IOSO NM |

|

Variable Valve Actuation analysis.

Valve Lift Diagram with

variable valve actuation can be setup and optimized individually for every

operating mode.

The Valve Dwell optimization takes also into account the duration and valve

lift of the dwell |

|

|

Advanced Ignition delay prediction model

The classical equations intended

for Ignition Delay prediction do not work properly at modeling PCCI

and under other conditions characterizing large EGR, small temperature, long

period of the delay, etc.

The Detail Chemistry is modeled for these cases, and

Ignition delay is calculated as a function of pressure history, temperature

history, EGR history and current Air/Fuel ratio for diesel fuel as well for

bio-fuel. The Lawrence Livermore National Laboratory mechanism which

considers 1540 reactions between 160 species is used.

A User Defined Model may be used for ignition delay

prediction. There is ability to link User Model DLL with DIESEL-RK

SAE Pap. No. 2010-01-1960 |

|

Simulation of engines with few Fuel Injection systems

DIESEL-RK supports simulation of an engine having up to 5

independent fuel injection systems (marked as A, B, C, D, E). Every system

may have own configuration with own number of injectors, mounted in

different places of the cylinder. Each injector may have few nozzles with

individual orientation in both planes and different diameters. Each

fuel system may have own cycle fuel mass and own injection profile. So the

Sequential Injection Profiles are supported at Heat Release simulation and

NOx simulation.

Because each system can inject own fuel the Dual Fuel

Engine simulation is supported.

|

|

|

Dual Fuel Engine Simulation

DIESEL-RK supports simulation of an engine having up to 5

independent fuel injection systems. One of the system may assigned as Pilot

Diesel Injection System; and another as Main Alternative Fuel Injection

System.

See details >>.

|

Water Injection DIESEL-RK supports simulation

of an engine having up to 5 independent fuel injection systems. One of

the system may assigned as Water Injection System (system D in the picture).

There is possibility to select place of H2O injection, cycle mass, timing

and duration of water injection. DIESEL-RK will simulate condensation and

evaporation of the water in all engine's gas flow path including cooler,

manifold, ports and cylinder. Effect of water injection is accounted in NOx

formation model which uses Detail Kinetic Mechanism. In the output data the

mass fractions of liquid water and water steam are presented as diagrams vs

CA and as integral parameters.

|

|

|

Coupled simulation of the mixture formation and combustion and prediction

of the thermal state of engine components.

Fuel evaporation and combustion as well as heat losses to the walls are

calculated using local wall temperatures obtained with the use of Finite Element

Model of main engine parts. Boundary conditions depend on the cooling system

design and piston ring assembly.

The program includes data base of geometry of:

- pistons,

- liners and cylinder heads;

which will be reflected by a preprocessor.

|

Being professional, the DIESEL-RK can be also used with success by beginners,

students and post-graduate students of high schools. For simplification at times

labor-intensive process of data set (especial empirical coefficients) in the

program a special tool is developed:

Wizard of New Project

Creation. This wizard on the basis of the most common data about

engine will create file of input data, using the most known technical decisions

accepted in area of propulsion engineering. Thus it is becomes simpler not only

a process of input data entering but also the most difficult stage of

computational research: calibration of engine models. The last is especially

important for the engineers who are not having enough time and experimental data

for customizing of the program on object of research, and also for researchers

who makes express engine analysis.

Skilled expert can use all abilities of advanced simulation methods of the

DIESEL-RK software by calibrating models with coefficients obtained on

experimental data.

Calculated curves can be exported via clipboard into external

applications (Excel, etc.).

Calculation of NOx emission is carried out by two ways. User can select NO formation model

from the list:

- Zeldovich's mechanism taking into account

a chemical equilibrium of 18 species may be used for conventional diesels.

- Detail Kinetic Mechanism (DKM)

or correct prediction of NO emission in engine with large EGR, multiple

injection and HCCI (199 reactions, 33 species). DKM is supported by the local

release of DIESEL-RK.

In the local version of the software the User Defined Models may be

implemented for:

- Friction losses simulation;

- Ignition Delay simulation;

- Forming and calculation of a Target Function for optimization Complex of

emission (NOx, Soot or PM and SFC).

Users Defined Models have to be developed by user as DLLs. Examples of

FORTRAN sources are presented in the distributive kit.

To make the DIESEL-RK be accessible to users, the remote

access via INTERNET is provided. For remote access

to the program it is enough to download file with

SETUP.EXE and to install client software on local computer.

List of input engine data

can be downloaded here.

|